Displacement cooling allows incoming supply cold air to push older hot air away without mixing with it.

Displacement cooling allows incoming supply cold air to push older hot air away without mixing with it.

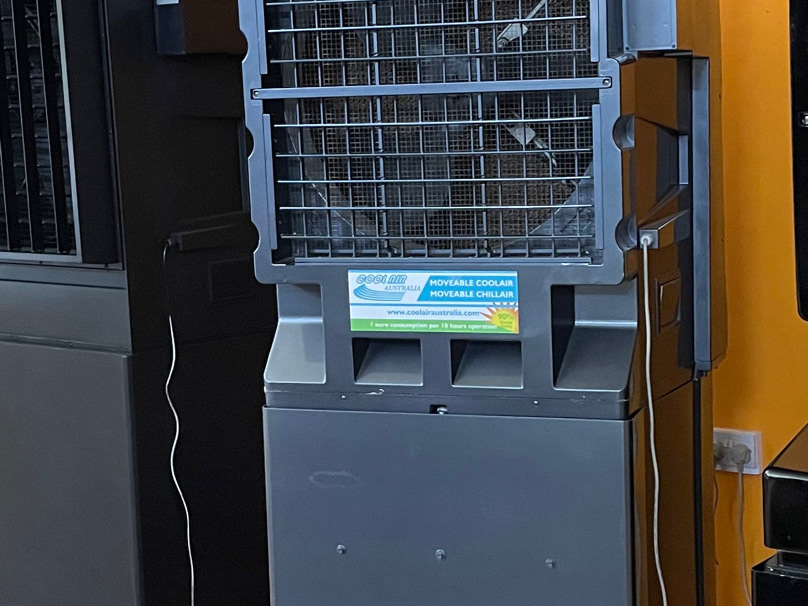

Displacement cooling solution for hot restaurant kitchen Kitchen Ventilation The effectiveness of ventilation effectiveness is the ability of the ventilation system to achieve design conditions in the space (air temperature, humidity, the concentration of impurities and air velocity) at minimum energy consumption. The air distribution methods used in the kitchen should be one that provides adequate ventilation in the occupied zone, without disturbing the thermal plume. In the case of a commercial kitchen, the airflow rate required to ventilate the space is a major factor that contributes to the system energy consumption. Traditionally high-velocity mixing or low-velocity mixing systems are taken into consideration. An alternative that clearly demonstrates improved thermal comfort over mixing systems, is displacement ventilation. The supply of air (make-up air) can be delivered to the kitchen in two ways: • high velocity or mixing ventilation • low velocity or displacement. The airflow and air distribution methods that are used in the kitchen should be one that provides adequate ventilation in the place where it is installed, without disturbing the surrounding air as it rises into the hood system. As per the standards states ventilation rate over 40 vol. /h effect on the basis of the heat load may influence to droughts. The location of the installed ventilation is also important for providing good ventilation. Ventilating systems should be designed and placed so that the ventilation air is provided equally throughout the occupied zone. Locating the supply and exhaust units too close to each other, causing ‘short-circuiting’ of the air directly from the supply opening to the exhaust openings are some common faults. Installation of supply diffusers of high velocity close to the hood system leads to a reduction in the ability of the hood system to give ample capture and containment (C&C) of the thermal plume. It is a known fact that the type of air distribution system utilised affects the amount of exhaust needed to capture and contain the effluent created in the cooking process. A properly designed and sized kitchen hood will ensure that effluents and convective heat (warm air) from the cooking process are captured; however, it is not sufficient to ensure the kitchen space temperature is comfortable. The radiation load from appliances under the hood, heat from appliances not under the hood, people, lights, kitchen shell (heat transfer through walls and ceiling), solar load, and implied heat and moisture from untreated makeup air are to be managed by the kitchen air conditioning system. It is recommended that a negative air balance be maintained in the kitchen. A simple rule of thumb is that the amount of air exhausted from the kitchen should be at least 10% higher than the supply air flow into the kitchen. This will guarantee that the odours from the kitchen do not spread to the adjacent spaces. DISPLACEMENT VENTILATION—THE MORE EFFICIENT WAY TO COOL A KITCHEN Most conventional kitchens use mixing ventilation to cool the space. In mixing ventilation systems, cool conditioned air is typically supplied through ceiling diffusers at a high discharge velocity. This high velocity is required to create a high momentum air jet for efficient mixing of supply air with room air. This air distribution system may not neces- sarily be the best fit for a commercial kitchen for two reasons: 1. High discharge velocity from mixing diffusers creates unwanted air movement and cross-drafts in the kitchen that make it difficult to capture and contain the plume from cooking appliances with the hoods. 2. All the heat rising from multiple heat sources in the kitchen is mixed within the space. An alternative air distribution system—thermal displacement ventilation (TDV)—is a better fit for the kitchen environment. In TDV systems cool air is supplied at low velocity directly into the occupied zone. Rather than mix the heat and contaminants in the space, as the mixing system does, TDV stratifies and displaces them out of the occupied zone into the upper part of the space. As a result the air velocity in the space is low, with no undesired cross-drafts, which makes it easier for the hoods to capture and contain plumes from cooking appliances. In fact, the hood exhaust airflow can be reduced by 12.5 % (VDI 2052 1999) when a mixing air distri- bution system is replaced with TDV. The space temperature, especially in the lower occupied part of kitchen, is much cooler with the displacement ventilation system than with the mixing ventilation system. A more accurate comparison of the temperature difference between the displacement and mixing ventilation systems at various heights in the room is clearly understood in field practise by the kitchen personnel who feel discomfort at the face level. It can be observed that at a head height of 70 inches (1.8 m) the displacement system has a temperature of 85°F (29.4°C) and the mixing ventilation system has a temperature of 98°F (36.7°C). This result shows that displacement ventilation can have a positive impact on comfort in the kitchen space. Besides occupant comfort, an additional benefit of using the displacement ventilation system is that it can improve the efficiency of the kitchen exhaust hoods due to a reduction in turbulence in the kitchen environment.